Colombia has a container and packaging industry that represents around USD 840 million in annual sales. The Latin American market is the second largest for personal care products and cosmetics packaging, and the third-largest for household cleaning product packaging.

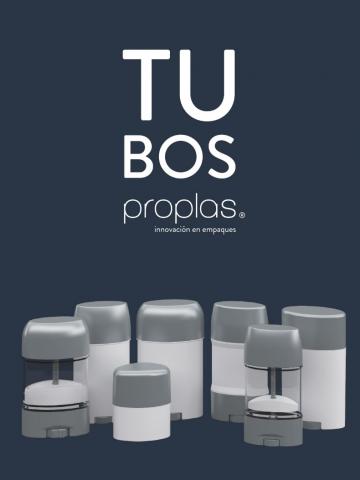

Plastic packaging has changed how manufacturing companies package and display their products. Different products require different packaging and this must adapt to the requirements of the products that are being packaged. Some products require packaging that is easy to store, others need for the packaging to tolerate different temperatures, accommodate different shapes, sizes, and colors. In recent years, packaging that is lightweight, durable, and comfortable are some of the factors that have augmented the use of plastics, making it one of the leading packaging materials across the world.

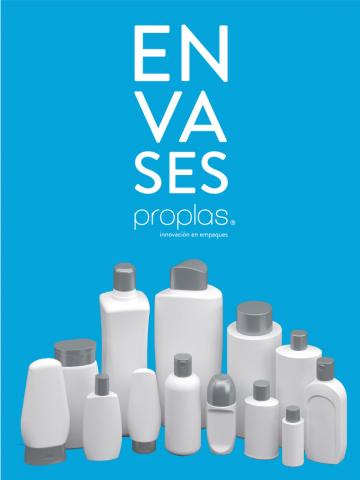

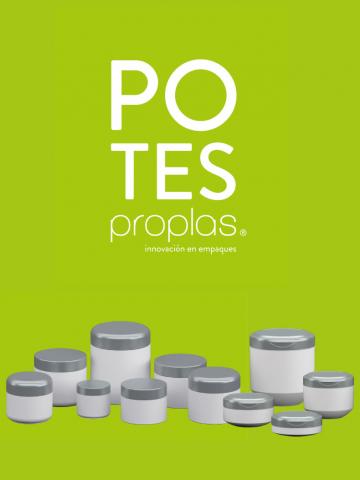

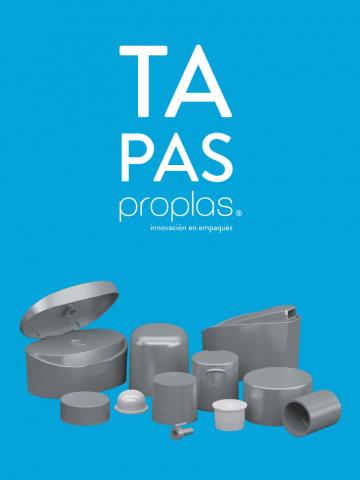

The industry has been interested in the integrated solutions that plastic packaging offers, such as flexible, printed, and disposable. There is a high demand in the characterization and integration of solutions through flexible packaging, folding boxes, containers, labels, preforms, bags, caps, disposable items among others.

Even though there are serious concerns about the impact that plastic has on the environment, the demand for plastic packaging continues to increase. The market will most likely face challenges with regards to government regulations and consumer demand, rerouting the manufacturer's way of producing. They will now be looking at the production of biodegradable packaging, or that derived from sustainable sources. Eco-friendly containers have become more and more popular in recent years, and the demand for this type of packaging will continue to increase.

Many of the packaging factories in Colombia have focused their production on cosmetics containers, cleaning products, and personal care products. Though the industry in the international market is competitive, Colombia accounts for high quality and reliable products that are promising to the market.

Pagination

- Previous page

- Page 20

- Next page